Natural Air Dried Wood

We build our fine art products from all species of natural air dried wood. Both semi-hard and hardwood species available. We never kiln dry, or force dry, our wood materials. Although this process requires a major investment in raw timber, large curing yards, and many years of desert air drying, we have always made the investment so we can produce the finest quality custom doors, gates, and furnishings for our customers.

Natural Wood Custom Furnishings

Natural desert air drying reduces wood warping, bowing, and cracking ten times better than kiln drying. Our natural air dried wood, desert air drying process allows for the very best wood joinery results, as well as drastically reducing warping, bowing and cracking by a factor of 10 over forced-air kiln drying. This means when your solid wood product re-moisturizes to your specific climate, indoors or out, it has a 98% better chance that these undesirable effects will not occur to your product. Contrasted to force kiln drying having a more than 50% probability of these above mentioned negative effects happening over a two to five year process in your climate - usually well after your limited warranty has expired.

Wood Species Education

We firmly believe that the more educated you are in natural materials, the better choices you will make when it comes to investing in quality custom furniture. The USDA report below will help you better understand each wood species. As tax payers, we spent millions of tax dollars on obtaining the facts about the hardness of all natural woods available on the planet used for furniture, doors, and flooring. This report was made available because our government recognized the benefit in real timber products, verses man-made faux building materials, and their relationship to a quality lifestyle. It was also used to eliminate the misinformation in the marketplace regarding building materials, and to further provide you with the proper information that allows you to make an informed choice in purchased furnishings.

Table of Contents

- - H. J. Nick - Artist Designer

- - Investment Quality Is Important

- - Guarantee & Satisfaction Warranty

- - How it's Made

- * Fine Furnishings Begin with Natural Materials

- - How It's Made - Wood Products

- - Master Hand Carving Information

- - How Its Made "Iron" - Master Blacksmithing

- - Facts About Leather Furniture

- - Stone, Marble & Granite

- - Art Factory Fine Art Finish Procedures

- - Finishes To World Class Antiquity Standards

- - American Vintage Restoration

- - More Door Details / Installation Info

- - Original Art or Limited Edition

- - Become an Interior Designer

- - A True Story About Mary

- - Dealer Design Policies & Rules

- - Web Site Terms And Conditions

- - Policies and Terms - A Must Read

This Chart Eliminates a lot of Misinformation by Many So-Called Experts

- Fact -- To build high quality furnishings you must start with the proper wood species.

- Fact -- Without the proper solid woods mortise and tenon joinery cannot be expected to stand the test of time.

- Fact -- All high value fine art products, antiquities, buildings, jewelry, etc., are made of natural solid wood, stone, gemstone, metal, or precious metal by the hands of master craftsmen.

A society that does not understand its history, or does not build on it, can have no expectation of immortality through its heirlooms, art, and antiquities, leaving nothing for future generations to build upon or enjoy. Therefore, in this fast - make it quick with glue and fake materials - designed to fit in a box - copying the world's fine art and antiquities for a fast buck - throw away world, your hard earned investment, along with your family's history in heirlooms, is being destroyed - one yard sale at a time.

Understanding Natural Wood - Product Value and Investment

By understanding natural wood and its relationship to your custom furniture, doors, gates, and furnishings, you can take the first step in getting real value, as well as ensuring your enjoyment and investment of any future purchases.

USDA - Janka Hardness Test - United States Department Of Agriculture Research Data

The Janka Hardness Test measures the hardness of wood.

It involves measuring the force required to embed a 11.28 millimeter (0.444 inch) steel ball into wood to half its diameter. This method was chosen so that the result would leave an indention 100 square millimeters in size. It is one of the best measures of the ability of a wood species to withstand denting and wear. It is also a good indicator of how hard a species is to saw or nail. The hardness of wood usually varies with the direction of the wood grain.

If testing is done on the surface of a plank, perpendicular to the grain, the test is said to be of "side hardness." Testing the cut surface of a stump would be called a test of "end hardness." In the United States, the measurement is in pounds-force (lbf). In Sweden it is in kilograms-force (kgf), and in Australia, either in newtons (N) or kilonewtons (kN). Sometimes the results are treated as units, e.g., "660 Janka". To convert the United States pound-force (lbf) units to newtons N multiply pound-force by 0.453 592 37 then multiply by 9.8. Janka hardness N = (lbf x 0.453 592 37)9.8 OR multiply by 4.44822161526. To get lbf from N, multiply N by 0.224808943099736.

A common use of Janka hardness ratings is to determine whether a species is suitable for use as flooring.

Wood Flooring Species -- Janka Hardness (pounds-force)

Wood Type |

Janka Hardness Rating |

| Lignum Vitae 4500 | 4500 |

| Brazilian Ebony | 3692 |

| Ipe/Brazilian Walnut/Lapacho | 3684 |

| African Pearlwood/Moabi | 3680 |

| Bolivian Cherry | 3650 |

| Lapacho | 3640 |

| Cumaru/Brazilian Teak (Somtimes): Brazilian Chestnut, Tiete Chestnut, South American Chestnut, Southern Chestnut | 3540 |

| Ebony | 3220 |

| Brazilian Redwood/Paraju | 3190 |

| Yvyraro | 3190 |

| Bloodwood | 2900 |

| Red Mahogany, Turpentine | 2697 |

| Southern Chestnut | 2670 |

| Spotted Gum | 2473 |

| Brazilian Cherry/Jatoba | 2350 |

| Mesquite | 2345 |

| Golden Teak | 2330 |

| Santos Mahogany/Bocote/Cabreuva | 2200 |

| Pradoo | 2170 |

| Brazilian Koa | 2160 |

| Sucupira (Sometimes): Brazilian Chestnut, Tiete Chestnut, Brazilian Walnut | 2140 |

| Brushbox | 2135 |

| Karri | 2030 |

| Sydney Blue Gum | 2023 |

| Bubinga | 1980 |

| Cameron | 1940 |

| Tallowwood | 1933 |

| Merbau | 1925 |

| Anendoim | 1912 |

| Jarrah | 1910 |

| Purpleheart | 1860 |

| Goncalo Alves/Tigerwood | 1850 |

| Hickory/Pecan/Satinwood | 1820 |

| Afzelia/Doussie | 1810 |

| Bangkirai | 1798 |

| Rosewood | 1780 |

| African Padauk | 1725 |

| Blackwood | 1720 |

| Merbau | 1712 |

| Kempas | 1710 |

| Black Locust Robinia_pseudoacacia | 1700 |

| Highland Beech | 1686 |

| Wenge/Red Pine | 1630 |

| Tualang | 1624 |

| Zebrawood | 1575 |

| True Pine/Timborana | 1570 |

| Peroba | 1557 |

| Kambala | 1540 |

| Sapele/Sapelli | 1510 |

| Curupixa | 1490 |

| Sweet Birch | 1470 |

| Hard Maple/Sugar Maple | 1450 |

| Caribbean Walnut | 1390 |

| Coffee Bean | 1390 |

| Natural Bamboo (Represents One Species) | 1380 |

| Australian Cypress | 1375 |

| White Oak | 1360 |

| Tasmanian Oak | 1350 |

| Ribbon Gum | 1349 |

| Ash (White) | 1320 |

| American Beech | 1300 |

| Red Oak (Northern) | 1290 |

| Caribbean Heart Pine | 1280 |

| Yellow Birch/Iroko Kambala | 1260 |

| Movingui | 1230 |

| Heart Pine | 1225 |

| Brazilian Mesquite/Carapa Guianensis | 1220 |

| Larch | 1200 |

| Carbonized Bamboo (represents one species) | 1180 |

| Teak | 1155 |

| Cocobolo | 1136 |

| Brazilian Eucalyptus/Rose Gum | 1125 |

| Makore | 1100 |

| Peruvian Walnut | 1080 |

| Boreal | 1023 |

| Black Walnut/North American Walnut | 1010 |

| Teak | 1000 |

| Sakura | 995 |

| Black Cherry/Imbuia | 950 |

| Boire | 940 |

| Paper Birch | 910 |

| Cedar | 900 |

| Southern Yellow Pine (Longleaf) | 870 |

| Lacewood/Leopardwood | 840 |

| African Mahogany | 830 |

| Mahogany, Honduran Mahogany | 800 |

| Parana | 780 |

| Sycamore | 770 |

| Shedua | 710 |

| Southern Yellow Pine (Loblolly and Shortleaf) | 690 |

| Douglas Fir | 660 |

| Alder (Red) | 590 |

| Larch | 590 |

| Chestnut | 540 |

| Hemlock | 500 |

| White Pine | 420 |

| Basswood | 410 |

| Eastern White Pine | 380 |

| Balsa | 100 |

Northern Cedar Cypress Wood

Due to our direct forest to mill processing, at ArtFactory.com we offer northern white cedar cypress for less than the lower priced woods below - with our guaranteed forever, no questions asked, unlimited guarantee.

The Hardness of a Wood Species is Not All You Need To Know - Experience Also Counts

Domestic Mahogany, All Pine Species, All Oak Species, Alder, Barn or Wormwood, and other hardwoods are available. You may choose to order any custom furnishing items made from mahogany, pine, oak, alder, barn or wormwood. However, due to the kiln drying process of these materials and their natural instability - even though these materials usually cost less than the higher quality northern white cedar cypress wood - we have found over the years that these woods do not hold up or stand the test of time as well as northern white cedar cypress. Therefore, we can only offer 12 months conditional warranty against structural failure on these particular woods, especially if used for outdoor exposed products.

ArtFactory.com Is Green Planet Friendly

We never use living trees that are felled for the purpose of manufacturing unless they are renewable resource. Most of our wood comes from trees that are considered destroyed by natural causes such as fires, storms or natural erosion. We also focus on American domestic timber that we can see the source, disinfestation is certified and it has employed properly paid American workers. EPA Reports. No old growth trees are cut for our products. Learn more about the Libocedrus decurrens species of wood used at our custom furnishings factory.

When you choose exotic cedar cypress wood in place of other woods you get a superior product and you save the cutting of non-renewable resource live trees and help our planet stay green. We salvage from nature and use every part of the northern cedar tree or Port Orford Cedar. Northern white cedar is not only a stronger wood, it is also one of mother nature's most beautiful woods with the natural grains and knots, as well as the fact that it is naturally impervious to elements such as moisture, wood rot and infestations. We consider the natural imperfections or distress markings of cedar cypress wood to be artistic and interesting.

We create no waste products that add to the world's landfills. The last cuts of all of our wood are used to build bird houses, feeders and other garden items, and sold with most of these proceeds donated to green planet non-profit organizations that aid in replanting the forest and other keep our planet projects. Also, ArtFactory.com uses these projects to help train the next generation of master craftsmen. Since most of our wood is Northwoods American cedar cypress, we chip what is left to be used as walkways, road beds, and garden cedar chips. The sawdust is all that is left and this is then put back to mulch the forest floor.

When you purchase an entry system or windows from ArtFactory.com you are choosing the most energy saving, thermal effective, products available in the world. We have always been earth friendly and all our finishes are water based and ecologically correct. Learn more about our eco-friendly process.

ArtFactory.com Timber Process

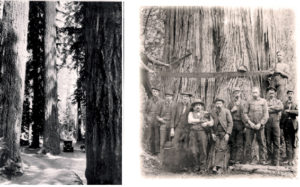

Great North Woods Forest 1928

This old growth tree was never cut down - only a photo opportunity.

Our old growth timber is acquired only when mother nature makes it available through peril, storm, natural erosion, or fire, or it has come from renewable resource timber meaning that the forest is growing from our planting programs more trees than are ever taken. We have been involved with planting conservation programs far before most were ever made popular or understood.

ArtFactory.com offers solid wood construction. When you order custom wood furnishings, doors, gates, built-in cabinets and other wood products you can expect superior quality and service. When we say a table top is 3" thick, we mean it is solid wood, 3" thick (not 3/4" of surface material and a 2 1/4" of boarder trim board to make it appear thicker). This method of solid construction is present in all our items and styles. This allows us to offer the only handmade, custom furniture and decorative accessory line with a "Guaranteed Forever" warranty. Our guarantee is backed by over a century as an experienced national U.S. manufacturer.

Our materials are processed and finished to achieve genuine authenticity.

Each item produced by ArtFactory.com is artistically designed from an original handmade work of art, and combined with the craftsmanship of a master craftsman, making it a unique work of usable collectable art. In order to achieve certain old patina appearances on the first day, the thickness of woods and types of joining required are pre-designed for each piece. In some cases, the material used is specially treated or expanded prior to assembly in order to allow for shrinkage after assembly. This creates an aged planking appearance and irregular natural warping or cracking normally found in old, authentic handcrafted furnishings. This process does not reduce the value of each piece because all we have done is speed up the aging process, we have not applied fake or faux finishes to achieve this look.

We have the ability to create solid slab tops and can tightly fit any design into a more conventional modern day style, simply specify when ordering. We can also create solid lumber, as thin as 1/8" to as thick as 12", without lamination to fit any special design requirements. We, at ArtFactory.com, are precise in our use of spacing, planking, cracked woods, pegging, and hand carving. We never beat up our wood with hammers and chains to achieve the imperfections that create a rustic look. The natural imperfections present in each piece are natural and are intentional. We believe these natural imperfections enhance each item and add artistic appeal while retaining their structural integrity.

All our timber is milled and naturally desert air dried and cured.

All natural air dried wood used in our custom doors, gates, furniture, and furnishings is dried on the desert floor (no forced air kiln drying methods ever used). Our exotic woods are naturally air dried on the desert floor for at least 12 months to less than 4% moisture content. Our old growth woods cure and dry time frame is sometimes as long as 5 years or more. We never kiln or force dry our wood. Force drying allows pockets of moisture within the wood that later can cause warping, bowing and cracking after the product is manufactured. Sometimes kiln dried woods will dry as much as 25% after the product is delivered to your home and climate. The outcome of kiln drying is usually never favorable.

Natural air dried northern white cedar cypress wood means structurally guaranteed "forever" no questions asked - this simply means if your product warps, bows, splits or cracks when it re-moisturizes in your climate and becomes structurally breeched - we will rebuild or replace your product at no charge to you.

Let's Talk Wood

Exotic northern white cedar cypress wood is rarely used by most manufacturers because of its cost versus the much lower cost of pine (barn wood), oak, alder or worm wood. Cedar is mother natures most beautiful and versatile wood, naturally impervious to insects and the elements. If you prefer your furniture or doors truly rustic with the natural divots, soft moisture incursions, additional knots and the distress of the inner core wood, we will cut from the oldest part of the tree or core. This natural capillary system (where the tree stores water as it ages) when exposed, possesses a character unmatched by any man made material. Since the holes and distress are natural in the core wood of the tree, they are structural - unlike worm wood, where the worms have destroyed the natural structure by eating the tree. Cedar can be kept outdoors in any climate without treatment. This type of cedar is rot and insect proof naturally in nature.

Northern White Cedar can also be cut from other areas of the natural tree and stained to look like pine (barn wood), oak, alder or worm wood. It can be sand blasted, grain raised or rough sawn to create almost any style of distress desired. We can also cut into areas of this tree with little or no distress, allowing you to order your desired natural wood appearance.

Northern White Cedar should not be confused with red aromatic cedar. Even though all cedar has the same basic natural qualities, the white cedar used in our hand crafted furnishings and doors is virtually odorless. Exotic northern white cedar is the main reason we can offer our Guaranteed Forever warranty.

All Species Of Domestic And Exotic Hard Woods Also Available

Some Family History We Would Like To Share

It is well known within our company, and the Marbella Family, that the founders were perfectionists. They were never satisfied with good and good enough. When the Marbella brothers first ventured out on their own, they were never satisfied with the common woods that were available and accepted by most master wood crafters as the materials used to make fine furniture in their day. Always being unsatisfied they began looking for what everyone in the industry told them was a impossible task. In fact no one hand found a better or new natural material that could be used to make fine furniture in over 100 years.

"The Impossible Just Takes a Little Longer"

This was the Marbella brothers motto; the rest is history. This motto is the heart and operating creed of H.J. Nick and ArtFactory.com on every creative process to this day.

It all begins when the Marbella brothers hear woodsmen tell of having seen stumps and trunks of trees lying on the ground, cut with obsidian stone axes, that carbon date back six to nine hundred years or more. As they searched for a better wood material for building, they began to listen to the stories told by woodsmen and other persons native to the national woodlands. These stories began in Row Mesa, New Mexico an area that has been home to Native Americans for thousands of years. These cedar logs can be milled into usable material after hundreds of years of lying on the ground. Stories about the tall stands of cedar come from as far and wide as the Great North Woods.

They began asking where all this timber was being used. They said it was not being used, because the established hardwood furniture craftsman of the day thumbed their noses at it simply because the center core was full of natural holes from the large capillary system within the tree trunks.

After much trial and error it became apparent that white cedar cypress wood was the solution

One problem remained. How would they get a ready supply of this raw material if it is not available cured and ready for milling? They came up with a feasible plan for natural air dried wood: desert air drying. This would require locating huge quantities of this material, cut at least two years in advance, then milling from the two year old end of the supply line.

This would require a large investment and a process would have to be developed to offset this cost.

Over many years, ArtFactory.com has perfected and protected this eco-friendly process. We acquire what the industry thought was not worthy of top quality craftsmanship, to create the finest quality furniture, cabinets, doors, gates, etc. found anywhere in the world today.

We feel the founders were right "The Impossible Does Take a Little Longer" and many of our customers agree it was worth the wait.

Learn more about our custom doors, gates, furniture, lighting, and furnishings from ArtFactory.com:

For more information about our products, please contact us at 1-800-292-0008.